- Overview

- Product Details

- Technical Data

- Company Introduction

- Why Choose Us

- FAQ

Basic Info.

Application

Industrial Magnet

Customized Support

OEM, ODM, Obm

Transport Package

Pallet/Air Carton/Express Packaging

Trademark

SYM

Origin

Zhejiang, China

Production Capacity

200, 000 Pieces Per Month

Product Description

Magnetic welding holders are designed to fix the ferrous metal parts by strong magnets for safe welding operation. It is an ideal tool for fast setup and accurate holding in welding process. The MINI magnetic welding holder set has 4 pcs with blister packing for welding angle 45, 90 and 135 degree.

| Model No. | Size | Angles | Pull Force |

| MT1010 | 2-3/8" x 2" | 45°, 90°, 135° | 9 LBS |

Neodymium Magnets Production Process

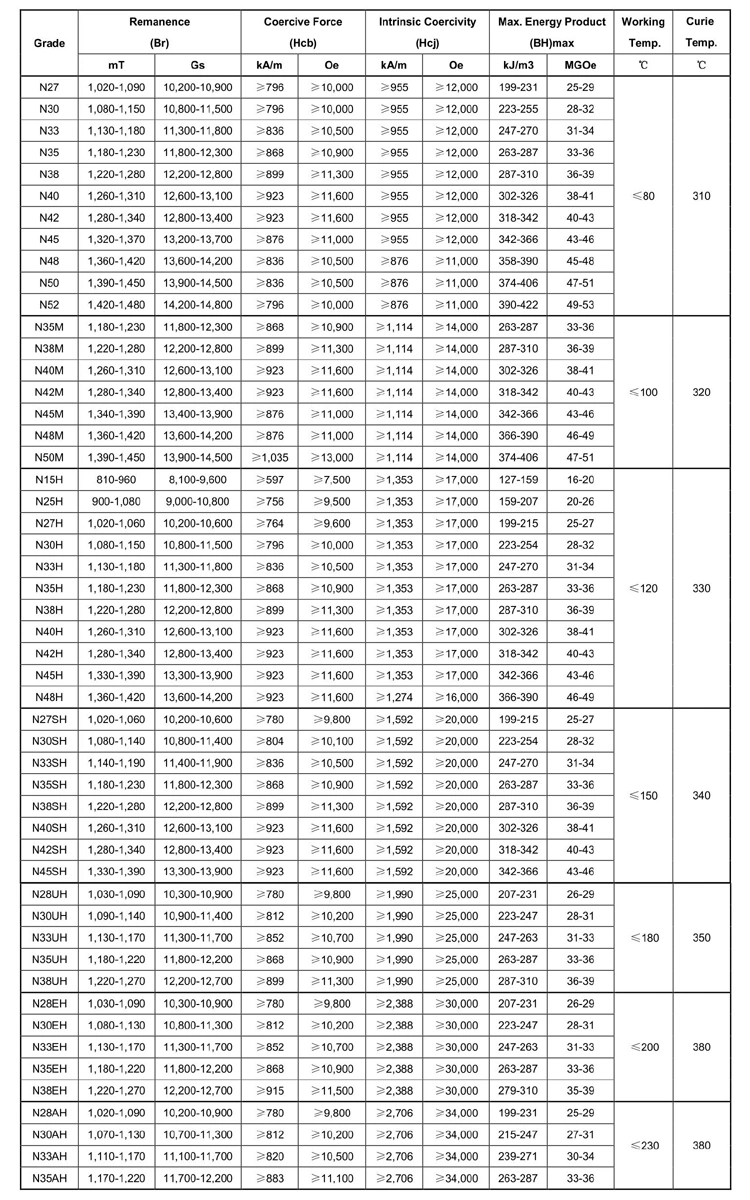

Neodymium Magnets Performance Datasheet

Neodymium Magnets Magnetization Directions

Neodymium Magnets Surface Treatment

| Surface Treatment | Process | Thickness | Color | SST | PCT |

| (μm) | (Hours) | (Hours) | |||

| Nickel | Ni | 10 ~ 20 | Bright Silver | > 24 ~ 72 | > 24 ~ 72 |

| Ni+Cu+Ni | |||||

| Black Nickel | Ni+Cu+Ni | 10 ~ 20 | Bright Black | > 48 ~ 96 | > 48 |

| Cr3+Zinc | Zn | 5 ~ 8 | Bright Blue | > 16 ~ 48 | --- |

| Cr3+Zn | Shining Color | > 36 ~ 72 | |||

| Sn | Ni+Cu+Ni+Sn | 10 ~ 25 | Silver | > 36 ~ 72 | > 48 |

| Au | Ni+Cu+Ni+Au | 10 ~ 15 | Gold | > 12 | > 48 |

| Ag | Ni+Cu+Ni+Ag | 10 ~ 15 | Silver | > 12 | > 48 |

| Epoxy | Epoxy | 10 ~ 20 | Black/ Grey | > 96 | --- |

| Ni+Cu+Epoxy | 15 ~ 30 | > 120 | --- | ||

| Zn+Epoxy | 15 ~ 25 | > 120 | --- | ||

| Passivation | --- | 1 ~ 3 | Dark Grey | Temporary Protection | --- |

| Phosphate | --- | 1 ~ 3 | Dark Grey | Temporary Protection | --- |

Remarks:

1. The SST results differ from coating. In general, Salt Spray Test result for the magnets with barrel plating (normally for small size of magnets), is better than the ones with rack plating (normally for big size of magnets).

2. Salt Spray Test (SST) condition: 5% NaCl, 35°C, continuously spray a certain time, test whether there is corrosion on plating/coating surface.

3. Pressure Cooking Test (PCT) condition: 2 atm, 95% RH (Relative Humidity), 121°C to test the plating/coating adhesion. (Zinc, Passivated/Phosphated, and Epoxy not suitable for PCT).

4. Other test methods for plating/coating: Drop Test, Cross Cut Test, Heating and Spilling Test, Constant Temperature, Humidity Test, etc.

1. The SST results differ from coating. In general, Salt Spray Test result for the magnets with barrel plating (normally for small size of magnets), is better than the ones with rack plating (normally for big size of magnets).

2. Salt Spray Test (SST) condition: 5% NaCl, 35°C, continuously spray a certain time, test whether there is corrosion on plating/coating surface.

3. Pressure Cooking Test (PCT) condition: 2 atm, 95% RH (Relative Humidity), 121°C to test the plating/coating adhesion. (Zinc, Passivated/Phosphated, and Epoxy not suitable for PCT).

4. Other test methods for plating/coating: Drop Test, Cross Cut Test, Heating and Spilling Test, Constant Temperature, Humidity Test, etc.

Physical Properties of Neodymium Magnets

| Curie Temperature (°C) | 310~380 |

| Maximum Working Temperature (°C) | 80~230 |

| Electrical Resistivity (µ.cm) | 110~170 |

| Hardness (Hv) | 560~580 |

| Density (g/cm3) | 7.4~7.8 |

| Relative Recoil Permeability (µrec) | 1.05 |

| Saturation Field Strength (kOe/kA/m) | (30-40)/(2,400-3,200) |

| Temp. Coefficient of Br (T.C.α (Br)) (%/°C) | -0.12 ~ -0.10 |

| Temp. Coefficient of Hcj (T.C.β (Hcj)) (%/°C) | -0.6 |

Hangzhou Shengyuan Machinery Co., Ltd. is specialized in manufacturing permanent magnets and magnetic assemblies. Our main products include neodymium magnets, SmCo magnets, AlNiCo magnets, ferrite magnets, pot magnets, magnetic hooks, fishing magnets, magnetic lifters, magnetic rods & grates, magnetic pushpins, magnetic tool holders and magnetic chucks, etc. We have a professional R&D team with plenty expertise and a sales team with rich experience in overseas business. Furthermore, all our products are manufactured with advanced equipment and strict QC procedures in order to ensure high quality. Our company's core value is "Building A Good Reputation With Quality Products And Excellent Service".

With the advanced management concepts and experienced team, we have exported our products to many countries and regions all over the world, especially to North America and Europe. Our products enjoy a good reputation among our customers.

We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

CONTACT US

Add: No. 200, Jianshe 1st Rd., Xiaoshan Economic & Technological Development Zone, Hangzhou City, Zhejiang Province, 311200 China.

1. Factory direct price makes our customers more competitive in the market.

2. OEM and customization is welcome.

3. Quick response to customers.

4. Professional R&D team with extensive expertise in the area of magnets and magnetic assembies . Most of our engineers at least have 10 years experience.

5. Advanced production and inspection equipment.

6. Strict quality control system. ISO9001:2015 and RoHS

7. Experienced logistics team to deal with FOB, CIF and DDU terms.

3. Quick response to customers.

4. Professional R&D team with extensive expertise in the area of magnets and magnetic assembies . Most of our engineers at least have 10 years experience.

5. Advanced production and inspection equipment.

6. Strict quality control system. ISO9001:2015 and RoHS

7. Experienced logistics team to deal with FOB, CIF and DDU terms.

-What information should I provide in my inquiry?

1. Model No. & order quantity.

2. Any special requirements for the packaging and transportation?

1. Model No. & order quantity.

2. Any special requirements for the packaging and transportation?

-How soon can I expect to get your reply?

Normally you can receive our reply within 1 hour during our work time 08:00 - 18:00(UTC-8).

Normally you can receive our reply within 1 hour during our work time 08:00 - 18:00(UTC-8).

-How will you ship the samples to me?

We will use international express such as FedEx, DHL, UPS and TNT. We have a good contract price with them.

-What is the normal delivery time for the customized magnetic rod's order?

The normal delivery time is 15-20 days.

-How about the payment methods?

We accept T/T, PayPal, Western Union and L/C